What Is Live Resin Delta 9

Delta 9 distillate is a highly refined cannabis extract, prized for its purity and high THC content. The distillation process employs advanced techniques to separate Delta 9 THC from other cannabinoids, terpenes, and plant materials. For those in the cannabis industry or enthusiasts looking to understand this product, knowledge of its extraction process is key to appreciating its potency and versatility.

Understanding the Basics of Delta 9 THC

Delta 9 THC, or delta-9-tetrahydrocannabinol, is the main psychoactive compound in cannabis, responsible for the euphoric effects of marijuana. When refined into a distillate, Delta 9 transforms into a clear, golden oil with THC concentrations often exceeding 90 percent. This makes it perfect for use in a variety of products, including vape cartridges, tinctures, edibles, and dabbing concentrates.

The Extraction Phase: Isolating Cannabinoids from Plant Matter

The journey to creating Delta 9 distillate begins with the extraction of cannabinoids from cannabis or hemp. This process typically uses solvents like ethanol, butane, or supercritical CO₂, each with its own benefits. The result is a crude oil that contains cannabinoids, terpenes, fats, and waxes. At this stage, the oil is not yet pure enough to isolate the desired Delta 9 THC.

Winterization and Decarboxylation: Prepping for Distillation

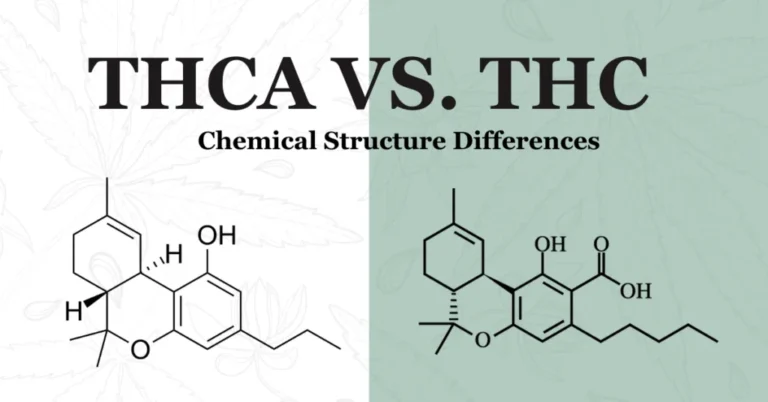

Following extraction, the crude oil undergoes winterization to remove unwanted plant fats, waxes, and lipids through a freezing and filtration process. This step ensures that the final distillate is smooth and clean. Next, decarboxylation is used to activate the THC by converting THCA, a non-psychoactive compound, into Delta 9 THC through heat. This step is crucial for achieving the psychoactive effects of the distillate.

Short Path Distillation: Purifying Delta 9 THC

The heart of the process lies in short path distillation, also known as wiped film distillation. This method uses specific temperatures and vacuum conditions to separate Delta 9 THC from other cannabinoids and impurities. By applying heat under vacuum pressure, the Delta 9 THC can be isolated without compromising its purity or potency, resulting in a clear and viscous distillate.

Quality Control and Compliance

The production of Delta 9 distillate goes beyond just the science; it also requires strict adherence to safety and compliance standards. Every batch undergoes laboratory testing to ensure it meets potency and purity specifications, free from harmful contaminants like pesticides, solvents, or heavy metals. Producers must follow both local and federal regulations, ensuring that their products comply with legal THC content limits and manufacturing practices.

Applications of Delta 9 Distillate

Once refined, Delta 9 distillate becomes a versatile product that can be used in edibles, vape cartridges, topicals, or consumed in measured doses. Its lack of flavor and odor makes it perfect for formulation, allowing for the addition of desired terpenes or mixing with other cannabinoids.

Precision Meets Potency

Creating Delta 9 distillate is a meticulous process that blends advanced extraction methods with chemical precision. From initial extraction to final purification, every step is essential to producing a high-quality, compliant product. As the cannabis industry continues to evolve, Delta 9 distillate remains a foundational product, valued for its potency, purity, and wide range of applications in both recreational and medicinal markets.